Transmission side of the Velocette two-stroke, which has been entirely redesigned tor 1920.

Steel cylinders may be a feature of the 1920 Velocette. The photograph shows two experimental types which have been undergoing tests

A commendable feature of the Velocette engine is its accessibility. By removing the retaining disc and withdrawing the compression plate the crank and big end are exposed, and, when necessary, the crankshaft withdrawn.

The aluminium piston. Note the extremely narrow rings,

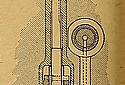

The mechanical pump, showing the oil channel to main bearing.

The rear hub of the Velocette lightweight, showing the internal expanding brake.

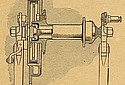

The new steering head design. Observe the lubricator at the top of the tube.

PROBABLY of all two-strokes the Velocette is regarded as the most economical, and, while there are others with which over 100 m.p.g. are regularly obtained, we do not recall readers' reports of any one make with which extraordinarily low petrol consumption has been so consistent. Some months ago we ran one of these miniatures and regularly obtained 145 to 150 m.p.g. on short journeys, under which conditions one naturally expects higher consumption than on longer runs. This point alone - accounted for by its mechanical lubrication - places the Velocette in a class almost by itself, of particulars of the 1920 models- which embody some of the war experience bf their designers - cannot fail to interest '.he followers of two-stroke evolution.

The three-port two-stroke is the most simple type of engine it is possible to make, and there has been a reluctance on the part of designers to depart from its extreme simplicity by introducing mechanism which naturally increases its cost. They have contended that its extreme simplicity is the keynote of its existence - that, by making it more complicated and more costly to produce, it becomes a direct competitor to the four-stroke without the four-stroke's advantages and economy. There are others, however, who maintain that the undoubted advantages of the two-stroke make it worth while to develop it even at the expense of added mechanism and increased cost, and that, though it embodies as many parts as the four-stroke, such additions are justified, provided all-round efficiency is equal or in excess of a four-stroke engine of the same size and costing the same to produce.

No one will disagree with this, as, if a twin-cylinder impulse effect can be obtained by a single-cylinder engine, and if such an engine is so designed that its consumption figure is as good as a four-stroke, then additional mechanism is justified; even if it does slightly exceed the four-stroke single on this point, yet it is less than a four-stroke twin.

In this latter school of engine designers is Mr. Percy Goodman, of the Velocette firm, and his faith in the two-stroke system is in no way governed by its simplicity. Although his latest design, which is illustrated, and will be tried out in the A.C.U. Six Days Trial, is extremely simple yet nothing has been sacrificed to gain this end.

A Large Crank Case, Outwardly.

Probably the most interesting departure from usual practice is the crank case of the new Velocette. This appears to be extremely large as compared with the average two-stroke engine crank case; in fact, it somewhat resembles the case which would embody a gear unit. Of course, the oil sump is responsible for some of the bulk of this casting, the compartment containing the crank being extremely small. This takes the form of a circular recess with a long plain bearing on one side, the single-sided crankshaft being threaded through from the crank case. When this is done the "big end" of the connecting rod can be placed on the crank and held in position simply by a spring ring in a groove on the end of the crank. Even this does not appear to be necessary, as Mr. Goodman's own machine has done several thousand miles without a retaining ring. The crank has a balance wheel riveted to it on its outer side, so that the weight is more or less on, the centre line of the cylinder.

Reducing the Compression Space.

In order to reduce the compression space as much as possible, a cone member is inserted in the annular chamber, and positioned by a spigot shown in one of the illustrations. An outer plate is then screwed in by means of a special key, which engages two of the series of holes around the plate. This locks the cone member securely in position.

The magneto drive is by means of gears, and both magneto driving pinion and main drive wheel are carried on the flywheel boss. Thus by removing the nut at this end of the shaft the crankshaft may be withdrawn. Three wheels are used in the magneto drive, the centre one being of bronze, and carrying on its shaft a slow worm engaging a worm wheel on the vertical shaft of the mechanical pump.

Variable Mechanical Pump.

At the lower end of the shaft is a plunger 1/4 in. in diameter working in a sleeve which acts as a valve. As the vertical shaft revolves it rotates this sleeve, and a port cut in its side registers alternately with the intake and outlet ports in an outer sleeve. A cross pin on the shaft works through the sleeve on an inclined plane on the stationary outer sleeve, thus causing it to reciprocate as well as rotate, the reciprocating motion being governed by the adjustment of the screw at the head of the shaft. Thus the stroke of the pump plunger is variable.

It will be observed from the illustration that the plunger of the pump has a truncated piston above it; this acts as a second pump, which is used to lubricate the vertical shaft and the worm gear.

Drawing the oil through a strainer from the sump, the pump forces it through the main bearing into the big end. Centrifugal action then throws the oil on to the cylinder walls and small end. By slackening a nut at the base of the pump, the whole of the lubricating device may be withdrawn without emptying the oil in the sump.

This lubricating unit is an exceedingly nice piece of work, and has the virtue that when dismantled it cannot be reassembled except in the correct manner. The fact that no ball or spring-operated valves are used in its construction, and also that the pump is always immersed in oil, are points in its favour.

When the engine is running the head of the pump-shaft, which protrudes from the "crank case," can be seen rising and falling as well as rotating, and it is easily possible to ascertain the speed of the engine by timing this movement, since the pump-shaft speed is only 1 revolution to 75 of the flywheel.

Piston and Cylinder.

The piston of the new engine is of aluminium alloy, and inside the head are cast a number of radiating ribs. Two very thin rings are fitted. The cylinder on the model we examined was of cast iron, but many experiments have been and are being made with steel cylinders, the results of which give good promise for the future. In all probability steel cylinders will be fitted as standard on all 1920 models, but until this feature has been proved, and the results are to the entire satisfaction of the makers, nothing will be decided.

We saw several steel cylinders, and learned many interesting details concerning the results obtained from them. One of the illustrations shows a cylinder which is the forerunner of the design which may make its debut in the A.C.T.U. Six Days Trial.

This cylinder is turned from the steel bar, and has twenty-four very thin fins. The ports are machined in a finless portion of the cylinder, thus rendering it possible to accurately portioned positioned This part of the cylinder is circled with aluminium member which embodies the transfer passage and intake and exhaust ports, and has a number of deep radiating fins

This jacket is made in two pieces fitted tightly against each other on one side and with a certain clearance, when cold, on the other to allow for expansion. At the top and bottom the jacket is fixed by the adjacent steel fins being spun over the aluminium member. In all probability the steel cylinder which will be used in the Six Days Trial will have fins increasing in diameter as they approach the head, while vertical fins may be used on the head itself.

The Compression Ratio.

So far, we understand, experiments have proved that it is possible to carry the compression to a higher point with this type of cylinder than is usual. As an example of this, in the old Velocette engine, with a "capacity" of 220 c.c, the volume of the combustion space was 52 c.c., and, after deducting the useless cylinder area (below the ports of a two-stroke cylinder), the actual capacity of the engine was 150 c.c. It will be seen this is a ratio of "approximately 4 to 1. With a steel cylinder, an engine has been run with a combustion space as small as 5 to 1 ratio, but this, naturally, overheated, and may be taken as the other extreme. However, during these experiments, the cylinder head was red hot, and the moving piston could be seen through the glowing metal, but the aluminium fins at the base were sufficiently cool to allow one to rest the hand upon them. Mr. Goodman is now experimenting to find the compression ratio most suitable, and anticipates that he will obtain increased efficiency through being able to carry the compression to a point not hitherto attained in air-cooled engines of the two-stroke type.

The new machine is very neat in design. 24in. wheels are retained, but the section of the tyres is increased to 2 1/4 in. The frame has a sloping top tube and duplex front tubes, but, on the whole, follows well-used practice. The details are good, especially the rear expanding brake, the spring-up stand, and the steering head. The last named is provided with a large lubricating orifice at the top of the steering tube.

As far as possible, black finish is used, and, with its gold-lined tank, the little Velocette looks very smart.

As hitherto, the Velocette for 1920 will be chain-driven and fitted with a countershaft gear box. These will be of both the two-speed and three-speed types, with kick-starter and clutch optional. Both gear boxes are exclusively of Velocette design.

The equipment includes C.A.V. magneto and Brampton forks.

The Motor Cycle, August 21st, 1919. p201