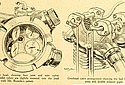

Triumph Ricardo 4-valve engine, 1921

THE TRIUMPH-RICARDO ENGINE

1. Timing gear side. 2. Plan view. 3. Driving side.

Triumph Ricardo Cylinder Head, 1921

Detachable head, showing face joint and inlet valves raised. The inlet valves are slightly recessed into the head in accordance with Mr. Ricardo's patent. (Right) Overhead valve arrangement showing the ball bearing-rocker arms and double exhaust pipes.

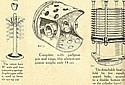

Triumph Ricardo Piston, Valve and Barrel

1. The valves have 30° seats and two concentric springs. A split taper collar is used to locate the spring cup. 2. Complete with gudgeon pin and rings, this aluminum piston weighs only 14 ozs. 3. The detachable head is held by five equally spaced bolts, secured to a double bottom rib on the cylinder barrel

The Motor Cycle June 2nd, 1921. Page 688

EVER since it was first known that the Triumph Cycle Co. had nominated a team for the 1921 Senior Tourist Trophy, an air of mystery has surrounded the entry. For some years past the 550 c.c. 4 h.p. engine has been the main production of the Coventry factory, and, since this type is too large to comply with the A.C.U. limits, considerable public interest has been evinced in the design of the new 500 c.c. mount.

We are now for the first time able to lift the veil, and disclose perhaps the most interesting machine which has ever left this world-famous factory.

The present engine, so far as the cylinder and valve gear and parts above the crank case are concerned, has been entirely redesigned by Ricardo and Co., Ltd., under the supervision of Mr. H. R. Ricardo. The modifications comprise ideas which embody the most up-to-date internal combustion engine practice.

It must be understood that the engine is still in the experimental stage, and that, before it is put into production, several further important alterations will be made, not only in the engine, but in other vital parts of the machine.

We gather that the Triumph Co. are entering the new engine as their second string, with a view to obtaining such valuable information as only a prolonged road race can provide, and that the Senior T.T. will form part of the strenuous road test to which all new Triumph models are subjected before being offered to the public.

Attention has been concentrated in this design upon obtaining and maintaining the greatest b.h.p. and speed revolution from an engine of given size, and to this end every detail has been have shaped. Thus we find a machined steel cylinder to avoid warping through uneven thickness of metal ; an aluminium piston to reduce reciprocating mass and to ensure that heat can flow away from the vital places multiple overhead valves of light reciprocating weight, seating in a special cylinder head approximately hemispherical in shape tor efficiency, and so constructed as to provide the best possible cooling. These points are but the skeleton of a design opulent in fine detail, and one which has already proved capable of remarkable performances from the angle of view of sheer efficiency. Having said that in the complete machine this engine drives a special two-speed gear box through an enclosed 1/4 x 5/8 in. chain and Triumph clutch and shock absorber, and that the final drive is by chain on the right hand side, we can now proceed to deal with the all-absorbing details, which are superbly carried out and merit careful individual consideration, since they are the outcome of some of the most able brains in the country, and show considerable originality as compared with accepted motor cycle practice.

Four Valves.

Commencing with the cylinder design, the detachable head is spigoted on to a steel cylinder, a plain ground joint being used for retaining compression. Five [?] bolts secure the head to the two lowest cylinder fins, which are milled out of the solid in such a manner as to form [?] at equally spaced intervals. At first sight, it may provoke surprise that the lowest ribs are utilised as a point of head attachment, but a little thought will show that by the employment of this method, unequal masses of metal are avoided on the hottest portion of the barrel.

Three circumferential ribs surround the base of the head, the remainder being exposed vertically. Two inlet and two exhaust valves are arranged in pairs at aproximately 90 degrees to each other, the former being contained in a common port, while the latter are separately housed and the ports lead outwards to corresponding exhaust pipes. The sparking plug is located in the centre of the head. Four drilled set pins screwing into steel bushes secure the cylinder to the crank case, this method being employed to save [?]ting the cylinder clear of the crank case studs, and thus allowing either the head alone or the cylinder and head as a unit to be removed with the engine in situ. .45% carbon steel is used as a cylinder material, and the bore is ground out to 80.5 mm.

Light Reciprocating Parts.

With the exception of the fact that the crank case has a flat base forming a all oil sump, the crank case may be passed over without comment, but it is interesting to observe that the flywheels have been slightly decreased in overall diameter, so as to increase crank case clearance and thus reduce oil friction.

A standard Triumph double row roller bearing is employed for the big end, and the connecting rod is of H section somewhat wider than that fitted to previous standard models. The small end is bushed with phosphor bronze, and the 17 mm. hollow gudgeon pin is allowed to float in both small end and piston bosses, being located endways by spring rings.

A very light aluminium Ricardo slipper piston, having two narrow rings, is used, and the gudgeon pin bosses are supported close to the centre to enable a light pin to be employed. The piston, complete with rings and gudgeon pin, weighs but fourteen ounces, while the complete reciprocating weight amounts to only nineteen ounces.

In connection with the silencing arrangements, it may be mentioned that brake tests have shown no loss of power up to 4,300 r.p.m., with expansion box and tail pipe in position.

Perhaps the most interesting feature of this unconventional engine lies in the valve gear. Primarily, it may be stated that a light rocker is interposed between each cam and tappet, and long ball-ended push-rods with adjustments at the lower ends are used to convey the motion to the one-piece nickel chrome rockers, which are carried in dustproof ball bearings housed in an extension of the head casting. Each valve, of 3% nickel steel (case-hardened), is returned by two concentric springs of only 25 lb. total tension, when the valve is seated. Separate cast iron valve guides are used ; the spring cups are retained by split taper collars screwed on the stem and pinned.

Masked Inlet Valves.

Masked inlet valves on the Ricardo system are employed for the first time on motor cycles, so that their salient features may require explanation, The valve heads are sunk below the level of the cylinder head, so that the first portion of the opening and the last part of the closing action are practically ineffective. By means of special cams the valves may be gently started and gently seated, though the effective opening and closing is sudden in each case. In this connection, it may be mentioned that the valve gear is noticeably quiet in action. Several types of carburetter, both automatic and two-lever, are being used for experimental purposes, but all are of considerably larger bore than that of standard motor cycle instruments, and specially large diameter petrol pipes are employed. It has been found, however, as a result of careful experiment, that an Amac carburetter gives the most satisfactory results on this engine.

Splash Lubrication.

No special system of lubrication is fitted, except for the fact that a very neat method of positive foot operation has been designed to force oil from a half-gallon tank, located behind the saddle tube, to the crank case.

After being subjected to prolonged bench tests of a most searching character, the first engine was taken to Brooklands, where it created something of a stir. We were permitted to observe certain tests, which proved most interesting.

During these trials, a lap of Brooklands was attempted on the low gear ratio of 5.6 to 1, and from a standing start an average speed of 60 m.p.h. was accomplished for a complete lap, equivalent in engine revolutions to about 4,400 r.p.m., or with slip allowance to 4,600 r.p.m. At the conclusion of the lap the engine was reasonably cool, and showed no signs of distress. The machine on which this trial was accomplished was in full touring trim, with mudguards, silencer, chain case, stands, carrier, etc., and was ridden by G. J. Shemans.

We are informed that since this time over a hundred laps at Brooklands have been covered at speeds varying between 65 and 79 m.p.h. Although these speeds appear highly creditable for a new machine, we understand that the designers are not satisfied that the maximum speed has yet been obtained. Their opinion is based upon the tact that figures from the testing works of the Ricardo Co. indicate that over 20 b.h.p. has been obtained which should certainly produce a higher maximum performance.

One is at first inclined to doubt the accuracy of such a high maximum horsepower from so small a cylinder, but we may state that we have personally had the opportunity of examining the testing apparatus, and we can affirm that it is so designed as to enable tests to be made with a degree of accuracy which is not obtainable with the type of testing gear ordinarily used.

Three of these machines will be in the Senior race ridden by G. J. Shermans, Stanley Gill, and C. Sgonina, in addition to six of the "side-by-side" type, which also has an entirely new engine. We propose to describe the more standard mount in our next issue.

Source: The Motor Cycle