"Triumph's 3½ h.p. model first appeared in 1907. Originally of 453cc, its sidevalve engine was enlarged to 476cc in 1908 and finally to 499cc in 1910 before being superceded by the 550cc 4hp model in 1914. Equipped with a three-speed Sturmey-Archer gearbox, it was this revised 4hp machine - designated the Model H - which performed such sterling service in WWI, with some 30,000 'Trusty Triumphs' seeing action with British and Allied forces. Soon to be updated with chain final drive, it became known as the 'SD' (Spring Drive) because of its clutch-mounted, coil-spring shock absorber and formed the basis of the later four-valve Ricardo model." ~ Classic Motorcycles Austria

The 1920 4 h.p. chain-driven Triumph. This model is fitted with an entirely new design of three-speed gear.

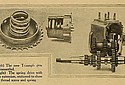

(Left) The new Triumph gear box dismantled.

(Right) The spring drive with clutch extension, sectioned to show quick thread screw and spring.

Micrometer adjustment for Triumph gear box. By turning the toothed plug, which acts on a rack in the top of the gear box, a fine adjustment is provided for the front chain.

The standard Triumph sidecar outfit. Lugs are formed integrally with the frame on this post-war model.

IT has long been an open secret that the Triumph Cycle Co. contemplated an all-chain driven model. Nine months ago we were permitted to make an extended trial of one of the early experimental models, which, we may say, demonstrated the advance made in single-cylinder machines for sidecar work. To a certain extent the firm showed their hand by entering machines of this type in the A.C.U. Trials - in which, by the way, the Triumph was the only single-cylinder sidecar machine to gain a gold medal. With characteristic caution and thoroughness, the Triumph Co. elected to try out every detail of the new model by continued and strenuous road tests before deciding to place it before the public as a finished article, and it was only on Monday last that the press were given an opportunity of studying the final design.

The 4 h.p. engine, which has already earned an enviable reputation for reliability and pulling power, both under strenuous war conditions and in everyday use, remains unaltered, save for special bosses on the crank case to provide fixings tor the chain case. It is in the transmission that the most important features lie, and these features are so pronounced that they are worthy of detailed description.

First of all the primary chain is enclosed in a special oil-tight case made of aluminium castings, held together by a series of studs. This case is fed with oil through a hollow stud in the lower part of the gear box, the oil being filtered through a gauze strainer before reaching the case. An overflow is provided to prevent an undue accumulation of lubricant, and a vent to avoid the possibility of air pressure due to heat.

Within the driven sprocket lies a disc clutch made up of seven pen steel and seven phosphor bronze plates held in contact by a powerful coil spring, the pressure of which can be released in a most ingenious manner.

Between the gear box and sprocket lies a fixed three-faced cam, engaging with which are three feet on a rotatable collar, the movement of which is controlled by the clutch lever. A movement of the clutch lever thus causes the feet, and, consequently the collar, to rise on the cams, and thus, through a suitable thrust race, to force outwards a clutch withdrawing flange.

This flange is fitted with three short pegs, which pass through the flange of the chain wheel and press against the clutch spring thrust race. By this means, the pressure on the clutch plates is relieved before any lateral motion of the chain wheel takes place. So much for clutch actuation; but the most interesting feature of the transmission lies within the diameter of the clutch spring, for the drive is not taken directly from the plates to the gearshaft, but passes from an extension of the inner clutch member through a quick-thread screw to a bronze member suitably and suitably mounted on the gearshaft.

This bronze member is normally pressed outward by a coil spring, but any sudden snatch, such as is caused by an engine pulling at slow speeds, causes the screwed member to be forced inwards against the action of the spring, thus permitting a certain amount of relative motion between the two screwed parts. In practice, this device forms a most efficient shock-absorber, and, though difficult to describe, is extremely simple and effective in action.

There is nothing to go wrong, and should the spring break (a most unlikely occurrence), the owner would be left with a rigid drive and could continue on his way until the replacement could be conveniently carried out.

The new Triumph gear box is a fine piece of work, the layshaft being of large enough diameter to permit the kick-starter spindle to pass through the inside. It is formed in one piece with all the gear wheels, and runs on large diameter caged ball bearings. Similar, but smaller, ball bearings support the mainshaft and top gear wheel, the shaft passing through a long hardened steel bearing in the gear wheel. A sliding member, composed of the low and middle gear wheels, slides on the mainshaft, which is suitably castellated. The high gear is engaged by the usual type of dog jaws. Middle gear is engaged through meshing the two spur wheels as in car practice, and low gear is engaged in the same manner, though, between middle and low, there is an interval in the castellations, so that the sliding member is free to revolve on the shaft.

Easy Gear Changing.

Another feature of the gear box is that when the gears are engaged there is practically no "back lash" in the dogs. This, of course, would be impossible if provision was not made for "centring" (sic) the sliding member before final engagement. This is done by means of a set of dogs having a great deal of clearance through which the dogs on the sliding member pass, thus being brought into direct line with the driving dogs for final engagement. This feature renders the gear box practically foolproof.

Primary Chain Adjustment.

The final drive is brought across to the right-hand side of the machine so as to be clear of the sidecar for inspection, and this chain is protected only on the upper side. The whole box is held up to the bottom bracket by four studs, and a particularly neat micrometer chain adjustment is provided. As previously mentioned, the kick-starter shaft passes through the centre of the layshaft, and a full gear wheel on the end meshes with a smaller pinion dogged to the chain wheel; thus the kick-starter operates directly and not through the clutch. The ratchet gear is positive and most ingenious, and the teeth are automatically tripped out of action when the starter pedal is returned to the normal position.

Integral Sidecar Lugs.

For the first time sidecar lugs are incorporated in the Triumph frame, and a beautifully finished Gloria sidecar, with spring suspension wheel, can be obtained with the machine, in combination form. At present, all Triumph models will be sold with the existing type of spring fork, but the enclosed spring type previously described in The. Motor Cycle of April 24th, 1919, will be standardised as soon as production facilities admit. In addition to the above model, which will sell at £110 solo, and £154 with sidecar, the well-known chain-cum-belt model, with Sturmey-Archer gear, can be obtained for £97 solo, or £141 with the same type of sidecar.

The Triumph Junior (two-stroke) remains unaltered, and will sell at £63. In addition, a 3 1/2 h.p. competition machine is on the stocks, but this will not be available for the public for several months.

The Motor Cycle, November 13th 1919. pp 535, 536