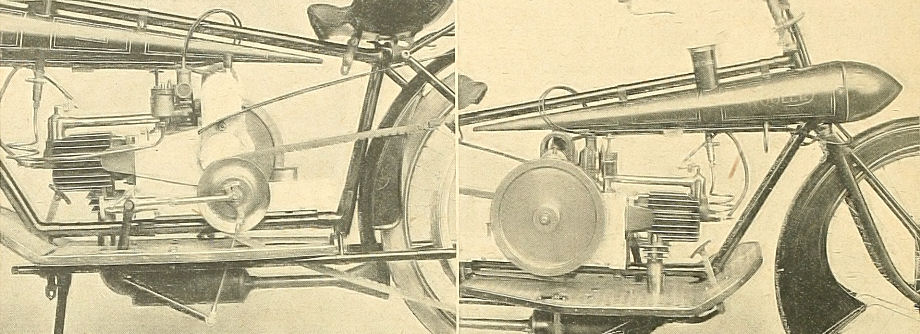

Pulley side of the engine showing belt tensioning device for variable gear. (R) The horizontal Wooler without side flywheel and footboards.

AN INTERESTING MACHINE, EMBODYING MANY DISTINCTIVE FEATURES.

THE Wooler has been on several occasions reviewed to in The Motor Cycle, and now the company has secured premises in Old Oak Common Lane, Willesden, for its manufacture.

Dealing first with the power unit, it may be remembered that the engine possesses many interesting features. It is of the two-stroke variety, the cylinder being placed horizontally, having radiating fins round the union of the exhaust pipe as well as on the cylinder itself. The first compression is made in the end of the cylinder opposite to the combustion chamber instead of in the crank case. The mixture is then transferred to the other end of the cylinder by means of an external pipe, which is clearly shown in the accompanying illustration. Lubrication is effected by means of a pump driven off the crankshaft, which delivers oil through a drip feed lubricator to the cylinder walls and to a jet which sprays oil. over the big ends. About one quart of oil, sufficient for two hundred miles, is carried in a separate container behind the clank else, the filler cap of which contains a squirt, which may be used for lubricating the various moving parts of the machine.

A novel arrangement is the interconnection of the drip feed and the throttle, so that the farther the throttle is opened the greater the amount of oil delivered to the cylinder, an exceedingly sensible arrangement, which allows the engine to get plenty of oil even though the road speed may be comparatively low.

The bore and stroke are 75 mm. x 76 mm. and the cubical capacity 344 c.c. The compression release valve is situated at the end of the transfer pipe, and when brought into action destroys all suction on the carburetter.

The parts are particularly accessible, and it is interesting to note that the power unit may be dismounted by undoing two nuts, while both the U.H. magneto and B. and B. carburetter can be got at with an equal amount of ease.

The torpedo tank is of neat design and pleasing appearance, and holds a gallon and a quarter of fuel. The illustration of the frame shows its neat construction, and the convenient form of back and front stands employed, while the two lugs for carrying the. engine are also clearly seen.

The Method of Springing

The Wooler is sprung fore and aft, the system of springing being a suspension of the wheel spindles on coil springs. The slots in which the spindles work are protected from dust by felt washers, wheel also retains the lubrication.

The arrangement of the change-speed gear is one of the most simple, being of the expanding pulley type and giving six forward speeds. The movable flange is worked by means of a quick screw thread operated by a heel and toe pedal.

The device shown forward of the gear in the illustration is for the tensioning of the belt. It has a movement of three inches, while tension can be effected by merely undoing a locking screw.

It is interesting to note that the brake rod runs inside one of the horizontal frame tubes, and is thus neatly concealed.

The Wooler is a machine the design of which has been carefully thought out, and is full of novel and interesting details.

The Motor Cycle, July 30th, 1914. p166

THE chief points of the interesting Wooler motor bicycle were recently dealt with in The. Motor Cycle, but there has lately been a small but important improvement added to the engine. This consists of an extra port in the cylinder, connected by a short tube to the centre of the induction pipe. The main portion of the gas enters the cylinder through the automatic inlet valve. The rest of the gas left in the pipe, being at high pressure, rushes into the cylinder as soon as the extra port is opened by the piston, at the end of the induction stroke, after the inlet valve has closed by the action of its spring. The effect of the incoming charge at the end of the stroke is to ensure the cylinder receiving a full charge of gas; it also greatly assists in the scavenging. The makers claim that the engine runs cooler, gives more power, still maintains its slow-running properties without four- stroking, and is capable of a better speed on the level.

Other small improvements are the addition of a grease cup to the timing gear, the fitting of a belt guard, and an extra long exhaust pipe, which issues from an expansion chamber close to the exhaust chamber. Its extremity is fan-shaped, and saw cuts are made at intervals in its length.

Yet another alteration is the fitting of a band brake to the front wheel, which possesses the advantage of not interfering with the removal of the wheel.

The improvement in the engine to which we have referred certainly causes the machine to develop extra power, and in the course of a short run we were enabled fully to appreciate the flexibility, power, and silence of this attractive little machine.

The Motor Cycle, November 26th, 1914. p595

Wooler Eng. Co., Ltd., Old Oak Lane Common, Willesden. British Lightweights, 1914