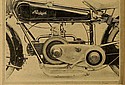

Transmission side of the 1920 flat-twin Raleigh. The engine is slightly enlarged, bore and stroke now being 77 X 75 mm. = 698 c.c.

Valve side of the Raleigh flat-twin. Note that the gear box is built into the frame, and that the silencer forms an underscreen.

Transmission side of the Raleigh power unit. The light portion of the flywheel is a lead insertion

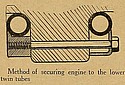

Method of securing engine to the lower twin tubes

SINCE we first described the flat twin Raleigh in May, 1918, there have been many detail improvements. Every little point has been carefully considered until the machine is well-nigh perfect.

The engine remains much as before, but the dimensions have been increased from 77x70 mm to 77x75 mm. bore and stroke, giving a capacity of close on 700 c.c, which means a little more power for sidecar work.

Roller bearings are used throughout, and a specially built-up crankshaft enables the cylinders to be very nearly in line without off-setting the connecting rods; moreover, the balance weights provided, combined with the very small offset of the cylinders, have the effect of practically banishing the small horizontal couple, which can only be entirely removed by making a three-throw crankshaft and using two light connecting rods to one cylinder, balanced by a heavier one to the other; this method does not wear well, and, where tried, has been abandoned.

Detachable cylinder heads are fitted, and these can be very quickly removed, for, on loosening a gland nut, the inlet pipe comes away with the head, and the exhaust pipe is so fitted that when its union nut is removed it does not impede the removal of the head; also it is gastight in any position which the union nut allows it to take up. '

A very effective shock-absorber is fitted to the engine-shaft, consisting of rounded projections on one part resting in depressions of a greater radius in the other. This gives an easy movement at first with a greatly increasing resistance as the spring is compressed. It is entirely automatic in action and cannot slip. The flywheel is loaded with lead.

The silencer, which also forms the underscreen, is provided with internal passages from each cylinder meeting in the centre and giving an inductor effect, the flow in each pipe being aided by that in its fellow.

As before, each valve is provided with two springs, whose period of vibration differs, the object of this being to stop bouncing.

Warming the Gas.

The induction of the charge still takes place through the timing case, a Raleigh feature which has been much copied, and a space is left below the magneto platform and above the crank case. This has the effect of improving the cooling of the front cylinder by allowing the stream of air, which is closing in after being disturbed by the front mudguard, a free passage over the cylinder, not interrupted by a solid erection on the crank case. An Amac carburetter (with either one or two levers) is bolted by means of a flange on the cover of the timing case, and is quite out of the way of the rider's foot or leg, which is not always the case on a flat twin.

Lubrication.

Oil is fed by a suction drip feed to a point in the crank case above the front connecting rod; this ensures the front cylinder getting its full supply of oil. The suction in the crank case is made very effective by the rotary release valve, which consists of ports cut in the shaft driving the magneto. Consequently, there is no possibility of a failure in the oil supply. This also has the advantage of allowing the warm air from the crank case to circulate around the inlet passage through the timing case, and warm the gas as soon as it reaches the engine.

A hand pump is also provided, by which an extra supply of oil may be given as occasion requires - for instance, in stiff climbing with a sidecar attached.

Gear Box and Chain Adjustment.

A new gear box has been specially designed for this model; it is housed in a casing which is built up in the frame - consequently, it is absolutely rigid, and cannot get out of line. These are very great advantages, but they necessitate shifting the engine in the frame for chain adjustment purposes. This is, however, accomplished in a very simple and satisfactory manner. An extension of the crank case projects downwards between the twin tubes below the engine; on each side of this are placed angle pieces, about six inches in length, and two bolts secure the whole. As the bolts are screwed home, the angle pieces meeting the curved sides of the tubes pull the engine downwards and hold it tightly. There is, moreover, a third attachment below the tank. The rear chain is adjusted as usual at the rear hub, and this can be done without disturbing or affecting the operation of the brake, which is of the internal expanding type, working within the rear sprocket. The clutch contains two plates, having cork inserts gripped between three plain plates, and the plate containing the driven sprocket is mounted on ball bearings. Both the main and lay-shafts of the gear are short, and of ample diameter, and, in consequence, are very stiff; the layshaft is geared down, and runs at low speed; this has the effect of reducing the loss of efficiency due to oil churning. Another point is that the sleeve carrying the driving sprocket is longer than usual, and takes a bearing on the main shaft at each end, with an oil chamber between. An enclosed kick-starter is provided.

The spring frame has been found to be so satisfactory that no alterations have been necessary. The construction of the gear box enables the joint of the sprung rear portion to be very close to ?the centre of the drive. The lower joints work on hardened steel bushes, those at the end of the springs on phosphor bronze.

With the exception of the top tube and head, the whole frame is duplex; this gives great strength and light weight, the actual weight of the complete machine is 280 lb.

Both chains are enclosed; the inside part of the front case is of cast aluminium, and is provided with a groove around the countershaft opening, in which the rear case (sheet steel) can rock as the spring frame comes into operation. This is made oiltight by means of a felt washer. Both mudguards are of ample dimensions, that in front being extra wide and, extending beyond the forks, is packed where the forks pass through to prevent mud from this point spattering the machine and rider. The footboards are of wood, mounted in. aluminium frames and rubber-covered. The rear brake is operated by the left heel, the front by the usual handle-bar lever. The brake rim in which the front brake acts is spoked, and attached to the hub in the same manner as the rear sprocket; thus, the wheels, as well as being quickly detachable, are interchangeable.

Detail Refinements.

Another important point, often neglected, is that an oiler is fitted through which lubrication can be supplied to the head bearings, both top and bottom.

The toolbox is situated below the tank in rear of the magneto, and is thus on the sprung part of the machine.

Other refinements consist of taking the operating wires partly through the handle-bars, handle-oar operation for the clutch, and an extension of the handle-bar stem to carry the head light. The stands are secured by spring washers to present rattling.

The Raleigh is designed both for solo and sidecar use, and should be most satisfactory for either. The riding position is delightfully comfortable and the saddle low. The sidecar is attached at four points to the main frame; in addition, a triangular member carrying the side-car wheel, which is sprung in the same manner as the bicycle, is attached at the top and bottom of the loop over the rear wheel.

The Motor Cycle November 20th, 1919. pp 601, 602