The new 2 3/4 h.p. O.K. flat twin as it will appear when complete.

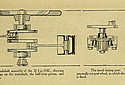

L. The crankshaft assembly of the 2 3/4 h.p. O.K., showing the roller bearings on the mainshaft, the half-time pinion, and the split big ends.

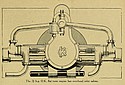

R. The novel timing gear. The cams are formed on an internally cut gear wheel, to which also the magneto chain sprocket is fixed.

The 2 3/4 h.p. O.K. flat twin engine has overhead inlet valves.

Every tube in the O.K. frame is straight. The vertical tubes of the carrier fit into split sockets on the stay ends.

A NEW model flat twin intended for solo work will shortly be introduced to the motor cycling public by the makers of the O.K. lightweight. This machine has been designed and is being produced by Messrs. Humphries and Dawes in their own factory, and will mark the entry of this firm into the motor cycle manufacturing field as distinct from that of assembling.

The war has wrought many changes, and it is necessary to obtain a different perspective of the various makes and makers from that of pre-war days.

Nearly every motor cycle manufacturing firm has considerably extended its factory during the last four years, while some have entirely outgrown the popular conception of their standing. It is permissible, perhaps, to class Messrs. Humphries and Dawes in this latter group, as while, before the war, their average output of motor cycles was comparatively small, their extensions during the past few years have increased their production capacity to between 200 and 250 machines per week.

The New O.K.

The new proposition is a flat twin solo machine, which has been designed with a view to meeting the requirements of a large section of the riding public at home and abroad. The first essential of the colonial machine is ample ground clearance, and on this point the new O.K. certainly scores with 7in. clearance, while large tyres are another Overseas demand, met in the new O.K. by 26 x 2 1/2 in. wheels, which on a 350 c.c. lightweight may be regarded as ample.

Duplex Frame.

Straight tubes are used throughout the frame which is of the duplex type, and departs in several ways from conventional design. In the first place, the top tubes both slope to the rear, but the lower members which support the tank drop at a greater angle than the tube over them. This is the reverse of general practice. On this point it may be said that fashion has been sacrificed for a more scientific design.

The steering head is a somewhat massive casting webbed at the rear, and embodying the lugs for no fewer than five tubes, of which the top tube of the frame is 1 1/16in., the duplex longitudinal tubes 3/4in., and the "down" tubes lin. The top tube terminates in a "seat" lug of the conventional type, and both pairs of tubes, which are a little over 2in. apart at their centres, connect with the single "seat" tube by neat U shaped lugs. The sloping front down tubes diverge towards the bottom in order to facilitate removal of the front cylinder, and are connected to the parallel horizontal tubes supporting the engine by means of double elbow lugs. The design at these points is shown in the drawing of the frame.

As before mentioned, there are no bent tubes in the construction of the frame. Where the rear stays are usually bent substantial castings are used on both lower and upper forks, two short parallel tubes being used to support the gear box, and a simple means of adjustment provided in the form of a draw bolt with locking nuts. The stays are made exceptionally wide to accommodate 6in. domed guards which are deeply valanced.

The 26 X 2 1/2 in. wheels are fitted with disc adjusting hubs and withdrawable bolts, the combination of which is novel so far as motor cycle wheels are concerned. Another feature of the frame part of the machine is the combined sheet metal undershield and footboards. The latter are covered with aluminium and are shaped and beaded at the edge. This unit is carried on the frame by two bolts, which pass through the sides below the footboards into lugs on each of the parallel tubes.

Flat Twin Engine.

From the size and general specification of the machine one expects an engine of greater capacity than 347 c.c. The first impression is that a lightweight engine is fitted in a "3 1/2" frame, which is due, no doubt, to the somewhat long wheelbase and the 2 1/2in. tyres.

The bore and stroke of the opposed twin engine are 60.7 and 60 mm. respectively, and it has overhead induction valves with enclosed operating mechanism, which is well lubricated through the tubular case enclosing the long tappet rod. This system has been proved to be most satisfactorily on one or two well-known engines.

Exhaust valves of generous dimensions are located at the side of the cylinder heads, and the shape of the combustion chambers and the size of the pockets should assist scavenging.

Timing Gear.

A distinctly novel system of valve operating mechanism is embodied. Two cams are formed on an internally cut gear wheel which meshes with the driving pinion. The sprocket for the silent chain driving the magneto is fixed the cam wheel, and the complete member is supported in a long bushed bearing which in turn is carried in a bracket fixed to the side of the crankcase wall by four studs. By removing four nuts the cam wheel and sprocket can be withdrawn with its bearing. The cylinders, which are staggered, have horizontal radiating fins, and are secured by means of two studs only. The connecting rods, on account of the staggering of the cylinders, are central with the pistons. Hoffmann roller bearings support the one-piece crankshaft, while split bearings, provided with bronze bushes, are used on the big ends. The lubrication will be on the splash system. A silent chain, enclosed in the timing gear case, drives the centrally disposed magneto. The carburetter will be an Amac.

The drawing of the engine shows somewhat long induction pipes, but we understand this point is receiving further attention on the part of the designers, and that in all probability the lay-out of the induction pipes will differ from the present design.

Mass Production.

Details are not available of the gear box, but we understand that it will be of the two-speed constant mesh type, embodying kick-starter and clutch. The transmission will be by chain to gear box, and final drive by fin. belt. The tank will have a capacity of two gallons. Up to the present it has not been possible to fix the price of the new machine, but we are told this will be in the neighbourhood of £50.

It is hoped, by the time the machine has passed through its tests, that the latest extensions to the factory will be complete. These will increase the floor space to approximately 15 acres The layout of the factory is such that the work progresses in one direction from the time it enters the receiving store until finished machines emerge at the packing shops near the railway siding, which runs into the works.

The work of Messrs. Humphries and Dawes during the war has necessitated installing an up-to-date plant in every way suitable for the mass production of motor cycles, and it is anticipated that an output of at least a hundred machines per week will be reached this year. Plans are being made, however, to increase this by over a hundred per cent.

War contracts included a great deal of tubular construction work, and the experience gained will be of inestimable value in the production of the new motor cycle, while it is the intention of the firm to maintain the rigid systems of inspection and the fine limits imposed by Government requirements to ensure accuracy and interchangeability. In .short, the O.K. firm intend to restart motor cycle production in such a way that no lesson of war work, which can be applied to motor cycle construction, will be wasted, and that their progress will be commensurate with that of the engineering world in general.

The Motor Cycle February 27th, 1919. pp 198-200