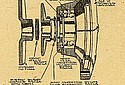

The compression retaining bearing and gland of the S type Metro-Tyler.

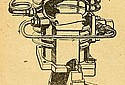

The lubrication system. Arrows indicate the path of the oil.

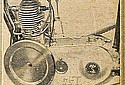

The Metro-Tyler method of enclosing crank case, magneto, and gear box.

A flexible pipe conveys the release gas to the chain case to lubricate the chain by oil vapour.

Some Details of an Interesting Machine.

WE know of few motor cycles fitted with two-stroke engines in which more careful design has been incorporated than in the 2½ h.p. S. type Metro-Tyler. Unlike many two-stroke lightweights, the Metro-Tyler has been most carefully thought out in every detail. The machine was described in our issue, for November 20th, 1919, but a few further remarks on its construction will not be out of place.

The engine and gear box are built up to form a single unit, the engine, magneto, and gear box being carried between two side plates, and entirely enclosed. The engine is naturally placed in front, next comes the magneto, and at the extreme rear the gear box. Both magneto and gear box are fastened m slotted holes so that movement is allowed for chain adjustment. The aluminium case, which encloses these three main parts, adds greatly to the appearance of the machine.

Two-speed Gear

Of the ordinary two-speed dog clutch pattern, the gear box has a main shaft running on double ball bearings on the pulley side and single ball bearings on the chain side, while the lay-shaft runs on plain bearings.

To show how carefully details have been studied, we may mention that there is not a nut, on the machine but which is secured adequately, either by means of a spring washer, a split pin, or by wiring the nuts so that they cannot move.

By boring the cylinders right through to the head and by machining the exterior as well as the interior, a perfectly smooth finish is secured in order to assist cooling. Bolted to the head is a series of. three aluminium cooling fins which assist in the radiation of the heat.

Crank Case Compression.

So far as internal parts of the engine are concerned it is worthy of note that a roller bearing connecting rod is fitted. Special care has been taken to render the main bearings compression tight, and this is effected by means of two fibre washers and a steel diaphragm pressing against a washer held by pins to the engine sprocket. By this means all danger of leakage is obviated.

Lubrication is effected through a drip feed provided with an auxiliary pump, the engine receiving the oil through crank case suction. There are two unions on the fly-wheel side of the engine. Through one the oil enters, and is carried via spiral grooves in the cylinder, out at the other union, and round to the induction pipe, through which it is drawn into the crank case, thus adequately lubricating the connecting rod and main bearings, the spiral grooves serving, of course, to keep the piston and gudgeon pin continuously supplied with oil.

Novel Exhaust Release.

It has been customary in the past in the design of some two-stroke engines to bring the gas from the release valve into the exhaust pipe, but in the case of the Metro-Tyler it is introduced into the unit cover so that oil spray from the cylinder is brought on to the magneto chain. Die castings are employed wherever possible, resulting in cheapness of manufacture and in an exceptionally neat and well finished appearance.

A point not often observed by motor cycle manufacturers is that of placing the date and type of the machine, and also the unit number, on the unit case, in a conspicuous position; so that the purchaser of a second-hand Metro-Tyler can make no mistake as to the date of manufacture.

The frame is also of great interest, as no lugs are used with the exception of the tank brackets, where brazing is employed all joints being acetylene welded. All back members, namely, the back fork and chain stays, have exactly the same contour on each side, so that the manufacture of these is considerably simplified. The chain stays are bored with two holes, one of these taking the mudguard support, while the rearward holes take the spindle for the foot brake on one side and the silencer bracket on the other. The toolbag is of triangular shape at the rear of the carrier. It is of metal, and is flitted with a spring-held cover, while the rearmost side is of the correct dimensions and so serves as a number plate.

The Motor Cycle August 5th, 1920. Page 176

Metro-Tyler. (Stand 51.)

2½ h.p.; 70x70 mm. (269 c.c); single-cylinder two-stroke; hand pump lubrication; Amac carburetter; C.A.V. chain-driven magneto; two-speed constant mesh gear; chain and belt drive; 26 x 2in. tyres.

Tyler Apparatus Co., Ltd., Bannister Road, North Kensington.

The Metro-Tyler is a small two-stroke which has acquired already a considerable reputation and has not increased too greatly in weight during the past few years, with the result that it still is a small and handy machine suitable for almost every class of work. The two-stroke engine is well forward in the frame, and has a decompressor facing forwards and just above the main exhaust pipe, which latter is carried back to a flexible pipe leading to the silencer clipped to the rear stays. There is a two-speed gear box bolted to extensions of the engine plates and driven by a chain enclosed in a casing, but the engine is made to look more than usually neat; in fact, in appearance to resemble a unit, by adding aluminium cover plates which extend from the crank case to the gear box on each side and render the exterior of the mechanism quite smooth. Beneath these cover plates is the magneto, which thus is effectively protected, in addition to the fact that the field magnets themselves are closed by end plates, and the magneto is, therefore, rendered waterproof. The Metro-Tyler also is one of few machines which have only footrests, these being preferred to the now popular foot-plates. One model was shown with disc wheels and one of a special chocolate colour, very prettily finished and altogether a most handsome small mount on distinctly speedy lines.

Olympia Show. The Motor Cycle, December 2nd, 1920. Page 729