A Brief History of the Marque

Manufactured in Germany, late 1930s

From the German MOTORRAD magazine, October 1938 (Translation courtesy Hartmut Schouwer):

In Italy five aero engineers once built the RONDINE. Now it's called GILERA and is destined to win a lot of races for the GILERA brand. When technicians do something with love, something good will turn out.

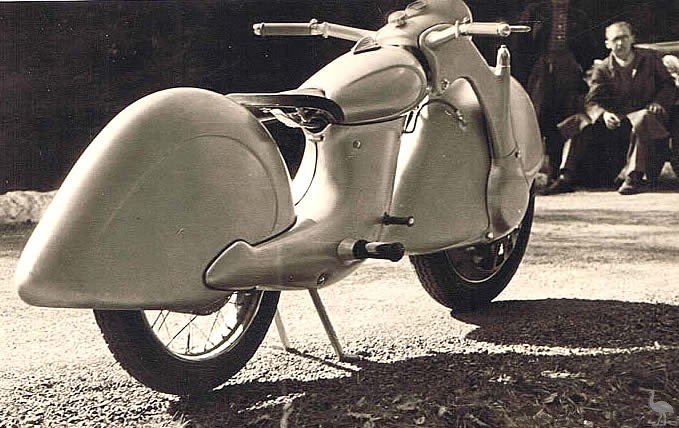

Three years ago five technicians from Munich started to design another nonconformist motorcycle, but they had another target: they created a modern bike with front-wheel-drive and aerodynamic, rational shape. That means a bike for daily use. And now it's ready for the show.

Our readers will remember the MEGOLA story. The magazine staff had restored an old MEGOLA to recollect the merits of this multiple-cylinder front-wheel-drive bike. We wrote: “Fantastic behaviour in curves . . . a child could ride it on sand . . .”

What the five technicians from Munich - the names of the designers/engineers are KILLINGER and FREUND - now completed is more than an improved MEGOLA. The engine displacement is again 600cc and it is also incredibly light: 135 Kilograms. (with fuel), but this bike has a three-cylinder two-stroke engine in the front wheel, it HAS a transmission and a clutch, it has a comfortable front and rear suspension and looks elegant and thrilling.

There's always a crowd of people around the displayed bike indicating that there's happening something great. If you join them and listen to them you will be astonished that most of them like the shape of this bike. That's important because the technicians wanted to build a bike that can be sold in large numbers some day. The people are used to aerodynamic shapes of car bodies now and it seems that they already expected something like that. The shape was developed to meet all these requirements: all moving parts covered, dirt protection, multi cylinder and front-wheel-drive. Another target was to reduce the numbers of different parts. This bike has less parts than a light 100cc-bike!

At first sight you realize the dirt-protective and aerodynamic covers of the front and rear wheel. Frame, fork and fuel tank are also aerodynamically improved. We were impressed by the nice details and good shaped transitions of the different body parts, as seen on race bikes.

And now the construction: the middle of the frame and the rear wheel cover are currently built as sheet metal shells around a tube frame. For the mass-production version there are plans to build the middle frame as a boxed frame, welded together from two pressed sheet metal parts. Of course this super machine has a rear suspension. It is linked to the lower end of the (inner) tube frame and fixed with flexible (rubber/metal???) elements which don't need any service. A lid in the box frame allows access to the seat springs to regulate the hardness of the seat's suspension.

The steering is like that of a normal bike, but the telescopic elements (80 mm lift) are more vertical than usual. That means that the wheelbase won't change much when the front fork dives in.

The front-wheel-drive is much better than the Megola design. First, the weight of the engine (unsuspended mass) is lower. The front wheel with engine has a weight of 50 Kilos. Second, a custom carb without a float needle doesn't have problems that could be caused by vibrations. And third, the light-weight battery ignition allows to start the engine without problems and helps to keep the engine weight low. The distributor and the points are located in the hub. The technicians originally intended to build a dynastarter. These improvements (plus transmission and clutch) had been impossible to add to the MEGOLA design.

The three-cylinder two-stroke engine uses a Drehschieber (= turning disk with a hole for more exact timing of the intake of the fuel-air mixture) [aka disc valve]. The fresh fuel-air mixture is sucked in by the vacuum in the three crankshaft housings as usual. The Drehschieber does the intake timing for all three cylinders. The engine is not a radial engine as known from planes. And there is no need for a flywheel. All three cranks seem to work on one common gear. This arrangement and the recoil of the pistons in the turning direction should secure a perfect balance of the moving parts. The cylinders are made of KS (brand name) iron cylinder walls and are totally embedded in the Silumin (kind of alloy) engine housing. Alloy cylinder heads with lots of cooling fins and the exhaust pipes are the only things that can be identified as engine parts between the spokes of the cast alloy wheel. These flat spokes are designed to serve as a cooling fan. The two-speed transmission is built as a differential transmission and uses slope-meshed gears. The clutch is made of usual clutch disks. The clutch (with the springs at the outer circle) is located in front of the transmission. The transmission is actuated by steel cables (foot-operated). All parts of the engine allow easy access for service work. After the removal of the engine - only two bolts and some wiring have to be removed - all important parts are within reach. The tire can also be removed easily. You have to unlock a safety mechanism and can remove the tire completely with the split rim. The front brake is installed in the hub. The rear suspension also has telescopic oil-filled shock absorbers. The gasoline runs down through flexible hoses.

Five men worked for three years on this machine. The bike was test-driven already and the engine was tested on a test-stand. As there are so many progressive ideas built into this bike, we hope that the developers will have a chance to complete their work, because we would like to experience the preferences of this bike some day:

Better handling - more safety - less weight - simple construction - no chain or cardan shaft - no valves - tangential arrangement of the cylinders for smooth engine characteristics.

Ch. Christophe

Many thanks to the person who sent the image above, which I believe to be the one published in Motorrad. Ed. That is the whole engine with transmission and clutch in the front wheel. You can see the three tangentially arranged cylinders and the cylinder heads outside the engine housing. The removal of the front wheel is just as easy as the removal of the rear wheel on a normal bike. The most interesting detail is the split rim, like those designed by Josef Stelaer for the BMW six-days competition bikes. This allows to remove the tire after unbolting some nuts and avoids the usage of a special two-ended air tube like in the MEGOLA (a “normal” endless tube could be used).

I've run across a couple of photos that might be of use for the Killinger and Freund (German) motorcycle page. It is interesting to see a U.S. Soldier on it as there was supposedly only one made and there seem to be subtle differences between the one in the other photos you have on the site, the one in the first photo attached, and the one which was obviously captured after WWII as to indicate the possibility that there might have been more than one produced. Of course over a period of seven years from the time of the 1938 production till the end of the war these changes may have occurred to the one unit. A very fascinating piece of history and one has to wonder what ever happened to it after it fell into American hands?

Sheldon Aubut

Houlton WI USA

http://www.sheldonaubut.com

Excellent page on the Killinger here:

www.berglaufpur.de/berglauf/Motorrad-FriedenstaubeFreundKillinger.htm

Friedenstaube Killinger und Freund art deco motorcycle 1938 - 3D Model

Sat Jan 18 2014

rmoore171 at gmail.com

Robert Moore

For all the world to know, my Dad ( a GREAT man ) is now vindicated.... I too have seen this thing. You see, my Dad was in WWll and often told me of seeing in a motorcycle with the motor inside the front wheel. When ask, how, he could not

explain it but said it was so. So, over the years, we used to tease him about this but he stood by his word that it was true... and now I have seen the pictures on the internet. This is indeed a strange looking beast at best. Ala. USA

Sat Aug 29 2009

callumansell at at hotmail dot com

Killinger and Freund Motorcycle

Hi I'm looking for a project and am very intrested in the idea of building (for personal use and showing off)a bike modeled on this design.

Are there any surviving blue prints/plans of the Killinger and Freund Motorcycle? would it be possible to get copies of them?

Thank you for your time. Looking forward to your response.

Callum Ansell

Darwin, NT, Australia

Fri Nov 27 2009

HARROsport at at kabelmail.de

Killinger and Freund Motorcycle

I'm searching for a complete machine or parts of it.

D-98559 Oberhof

Mon Nov 24 2008

bmwmotomanat at hotmail dot com

original WW II pictures

Killinger and Freund Motorcycle

I Found these original pictures of WW II when my grand father past away a few fears ago ,I know he served in the war but I have no idea where he got them ? So I scanned them and happy to share them .

Canada

Wed, 16 Feb 2005

subject: 1938 Killinger & Freund

Email: craig at craigvetter dot com

Further comments from Craig Vetter, Designer: This front wheel drive arrange is facinating. The overall design is inspiring. Assuming that the built in engine can be controlled, the only potential problem would be that of unsprung weight.

You want a light wheel and heavy body for a cushy ride. This is the opposite. How light could the engine be made? It has possibilities for sure. Brilliant piece

craigvetter.com

October 25, 2002

I located the Killinger & Freund page and found the following.

The following 10 statements are from this Killinger & Freund page..

My comments on the 10 items follow.

It is a very interesting concept. I see no reason why this would not function. I do see a very serious potential problem that would, in my estimation, cause early mechanical failure of the 3 engine(s) crankshaft gears mating to the flywheels ring gear.

A reciprocating engine has hi energy rotational, cyclic oscillations (radial power and inertial vibrations) that are damped out by the flywheels mass. If these vibrations and masses are not coupled directly, and are seperated by the gear clearance in this design, the gears will very likely wear out very rapidly,

I made a little free-hand sketch of what this power plant would approximately look like.

The piston travel is "Tangential" to the circumference of the flywheel.

And all other items mentioned are complied with, except the "Drehschieber" the rotary disc valve plate.

There are several methods of incorporating the Drehschieber in the sketch, but the sketch was getting crowded..

Regards,

Ralph-1 at webtv.net

If you have a query about Killinger & Freund motorcycles please contact us