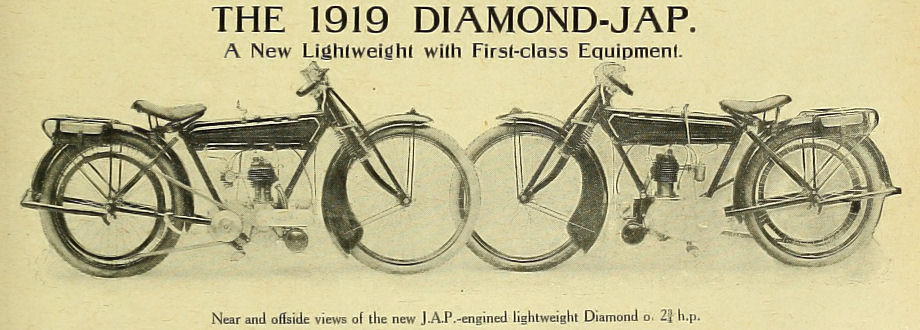

THE D. F. and M Co., of Wolverhampton, are the makers of the interesting shaft and chain-driven Diamond, but for the present they cannot proceed with the manufacture of this model, and are concentrating upon two-stroke and J. A. P. engined lightweights. The latter machine is a new model, and is now illustrated.

As will be seen from the photographs the engine fitted is the small single-cylinder J.A.P. with chain-driven magneto at the front of the unit. The bore and stroke are 70 X 76 mm. respectively (292 c.c).

An Enfield two-speed gear is the standard gear on this model, which is contained in an aluminium oil bath chain case, which also encloses the operating mechanism.

In producing this model the makers make no attempt to compete in price with other assembled machines which are similarly engined, but have endeavoured to produce a lightweight first-class at every point. 26 x 2in. extra heavy Dunlop tyres, Brooks B150 saddle, best class Bowden fittings, British-made variable magneto, Druid D.W. forks, Dunlop belt, Senspray carburetter, high quality toolbags, and well equipped tool roll are items of the specification. The makers' address is Vane Street, Wolverhampton.

The Motor Cycle February 27th, 1919. p210

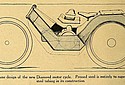

The frame design of the new Diamond motor cycle. Pressed steel is entirely to supersede steel tubing in its construction.

THE pressed steel motor cycle frame has long been regarded as an ultimate development, but until recently there has been no particular tendency in that direction, in spite of the many advantages which, theoretically, it presents. We have, however, foreseen that the war-time experience of several of our motor cycle manufacturers with engine plates for aeroplanes would influence motor cycle frame design. Therefore it is of especial interest to find the makers of the Diamond motor cycles, D.F.M. Engineering Co., Ltd., of Wolverhampton, well advanced in the production of the first models of a genuine tubeless frame constructed entirely of steel pressings. Before proceeding further, it is as well to state that this firm is not yet in a position to entertain any enquiries relating to this machine.

A glance at our illustration shows what a distinct departure it is from usual practice. The novelty is not merely confined to the frame, but the engine unit also is unique.

The frame consists of two side plates carried right through from the head, downwards, to form part of the engine carrier, and, upwards, over the back wheel, to form strengthening valances on the back mudguard. The two plates are connected behind the head by (1) a segmental plate covering the petrol tank, (2) by the tank itself when in position, (3) by a removable plate over the engine, and again (4) by the back mudguard. The whole is completely stiffened by the engine unit baseplate, which is bolted in from the under side.

All the plating, flanged for strength, is of stout gauge, the side plates being of lesser gauge than the top plates ; the head is formed in a separate piece with side wings, to which the side plates are bolted.

The Engine Unit.

The engine unit is complete in itself - so complete, in fact, that when the chain and petrol pipe are disconnected and the baseplate unbolted, it can be entirely removed from the frame, carrying with it the two-speed gear box, magneto, silencer, and carburetter. No part of the engine unit is attached to-the frame, yet so accessible is the engine that with the cover plate removed it is possible to make any adjustment, even to the removing of the outside flywheel.

The engine is of the four-stroke type and of 427 c.c. capacity, and is placed horizontally with side-by-side valves on top of the cylinder, but its general details we omit at present, as certain patents connected therewith are not yet completed. The same remark applies to the method of springing and adjusting the back wheel. That it follows car practice throughout and gives promise of excellent results is the most we can say at the moment.

There are numerous other interesting details, which will be dealt with later. We hope to have a machine on test shortly, when our actual experiences on the road with this unique mount can be given. As it stands at present, it presents no particular difficulty ; some faults may develop, but nothing which cannot be overcome. In this connection, the friendly criticism of readers of The Motor Cycle is invited.

The designer has been particularly careful to obviate any chance of side play or want of strength at the head, engine plates, and rear wheel. The machine will be suitable tor riders of either sex without alteration, and will be an undoubted advance on the point of cleanliness. The engine is completely shielded from the rider, and an ample dashboard and leg shields can easily be fitted, rendering the machine as nearly weatherproof as possible.

On the point of cost, whilst the preliminary models will certainly cost more to produce than a tubular frame, the saving when large numbers are built will be considerable.

The Motor Cycle, January 16th, 1919.

If you have further information or a query related to this page, please contact us