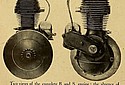

The 350 c.c. B. and S. engine with oil base and cylinder head removed. On the left will be seen the ribbed aluminium base, and on the right the sunk cylinder head with single piston ring. Crank-shaft, piston, and connecting rod may be removed from the machine through the base without detaching the engine from the frame.

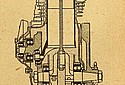

Section of the B. & S. cylinder, showing the arrangement of ports and gas passages

Two views of the complete B. and S. engine; the absence of external valve gear is particularly noticeable, and the clean lines obtained by combining the cylinder in the top half of the crank case, are also apparent.

The single sleeve valve of the B. and S. engine, to which a reciprocating and oscillating motion is imparted by means of a pin engaging with a Skefko ball race set eccentrically in the half-time pinion.

The crankshaft is supported in ball bearings, which are held up to the fop half of the crank case in suitable steel housings.

A waisted piston, having two top rings and one scraper ring, is connected to the crankshaft by an H-section connecting rod having a single row roller big end.

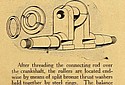

After threading the connecting rod over the crankshaft, the rollers are located end-wise by means of split bronze thrust washers held together by steel rings. The balance weights are attached after assembly.

Arrangement of sparking plug, and release valve, A somewhat modified form of piston is now in use.

Sectional elevation of the engine. Note the sleeve operating gear, which runs on ball bearings throughout.

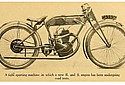

A light sporting machine in which a new B. and S. engine has been undergoing road tests.

Speed, Silence, and Accessibility combined in the New Barr and Stroud 350 c c. Motor Cycle Power Unit.

SINCE the introduction of the sleeve valve engine in the automobile world, there have been various attempts to adapt this form of silent valve operation for motor cycle work. Most of these efforts have proved fruitless, though the lure of the mechanically silent engine is strong.

Amongst certain conservative motor cyclists there is some amount of prejudice against sleeve valves, probably owing to their comparative novelty; but the fact must be borne in mind that some of the highest class automobiles in the world are fitted with sleeve valve engines. Such names, for instance, as Panhard, Piccard-Pictet, Daimler, Minerva, Mercedes, Argyll, and Willys-Knight have served to prove the reliability of sleeves, both for touring and racing purposes. It may be remembered that the team prize in the 1914 Tourist Trophy car races was obtained by sleeve valve engined Minervas, which finished second, third, and fifth; while some twenty-three long-distance Brooklands records still stand to the credit of the single sleeve Argyll car.

A Tried System.

This last fact has a special bearing on the matter in hand, for the record-breaking Argyll and the new Barr and Stroud motor cycle engine are both manufactured under Burt patents, and the motion of the single sleeve is similar in each case.

As long ago as November, 1919, we were able to give details of an experimental engine produced by Messrs. Barr and Stroud, of Anniesland, Glasgow, and since that time the firm has been active in perfecting the design and modifying details for production purposes.

The first production engines have now been completed, and have undergone prolonged road and bench tests, and towards the end of the year a limited supply should be available. Messrs. Barr and Stroud, however, do not intend to market their new production until they have ample stocks, though it is intended that large numbers shall be produced in 1922. Before proceeding to describe the engine, it should be explained that the manufacturers, whose name is well known as makers of range finders, fire control mechanism, and other precision instruments, are accustomed to manufacturing to extraordinarily fine limits, and from our own observation we may say that the workmanship of the new B. and S. engine is superb.

Valve Operation Described.

Though retaining the principle of the single .oscillating and reciprocating sleeve, the engine has been modified from its original form to a very considerable degree. The main dimensions are 70 mm. bore and 90.5 mm. stroke (349 c.c), and the iron cylinder barrel is cast in one piece with the top half of the crank case. Within the barrel lies a semi-steel sleeve about 3/32 in. in thickness, the base of the sleeve being stiffened up and carrying a pin, at right angles to its axis, through which the motion is conveyed. It may be remembered that in the early engines the sleeve was given a combined vertical and semi-rotary motion by means of a crank and link. This operating gear has now been superseded by a clever adaptation of a Skefko self-aligning ball race set eccentrically (and at an angle) in the half speed operating wheel. The pin carried on the base of the sleeve engages in the inner race of this ball bearing, and is a sliding fit therein. Thus when the half time wheel is rotated the sleeve is raised or lowered, and at the same time rotated through a considerable number of degrees, the self-aligning ball race adapting itself to the necessary positions.

It will be seen that any point on the sleeve follows an elliptical path. A stroke of only 1.4 in. is given to the sleeve, and the necessary balance weight is incorporated with the half time gear wheel.

Five ports of a form calculated to provide the greatest possible area are cut in the top of the sleeve, two acting as exhaust ports, two as inlet, and one as both inlet and exhaust, since the rotary motion of the sleeve causes it to register with an inlet port on one stroke, and an exhaust port on the other.

Simple Head Construction.

Six corresponding ports are formed in the cylinder - three inlet and three exhaust. Sunk inside the sleeve is the cylinder head proper, which carries a single ring at its lower extremity as an additional gas seal, and also the sparking plug and release valve. Exhaust and inlet gas passages are cast with the cylinder, so that a single external pipe is all that is necessary in each case.

A light cast iron piston of the Zephyr type, having two rings at the top and ail oil scraper in the skirt, is used, the hollow gudgeon pin floating in the piston bosses and being fixed in the small end of the H-section connecting rod. A single row roller big end is employed, the connecting rod being threaded over the solid crankshaft, and located sideways by split bronze thrust washers held in place by steel rings.

Balance weights are attached after the bearing has been assembled, and are permanently fixed in position.

Both sides of the crank are carried in large ball bearings, and these bearings are held up to the four foundation bolts by steel carrier rings; a ribbed aluminium oil base covers the mechanism.

The sleeve operating half-time wheel has wide fine pitch teeth, and is driven directly from the crankshaft, and the magneto, which may be carried either in front or at the rear, is driven through a train of gears.

Easy to Dismantle.

Great accessibility is a feature of the engine. By removing the oil base and four nuts, the whole piston, connecting rod, and crank assembly may be removed for examination without detaching the engine from the frame, while by removing three screws the magneto and distribution gears may be detached complete, and the sleeve lowered through the base.

On the bench the engine has given most satisfactory results, and the standard article produces over 6 h.p. at 3,000 r.p.m. This figure is by no means the limit, as the power curve continues to rise steadily to well over 4,000 r.p.m., and special engines with high compression and light reciprocating parts have given a maximum power of approximately double that already stated.

After a thorough examination of all parts, we were offered a trial run on a light machine fitted with the standard engine and an nil-chain drive Sturmey-Archer two-speed gear. Accompanied by Capt. Barr on another machine fitted with a brand new engine, we set out, having been warned that our mount was capable of a mile a minute under favourable circumstances.

The first noticeable feature was the entire absence of noise from the engine, with the exception of the exhaust. The distribution gear is inaudible from the saddle. There is not even a click to be heard from any other part of the power unit. A hum from the transmission chains and gears is noticeable, but not unpleasant. Next comes flexibility and top gear climbing, and it was found that the engine could hold a top gear of 5 to 1 on quite considerable hills even when these were approached at a crawl. And finally, where road conditions were favourable, we were able to try maximum speed. Unfortunately, no speed indicator was fitted, but we may safely assert that the new B. and S. is one of the fastest standard 350 c.c. engines which we have had the opportunity of riding. The engine was consistently smooth and silent in operation at all road speeds except the very lowest, when a slight vibration from the sleeve was noticeable; this fault, however, has already been corrected by a modification in the sleeve balance weights.

We were particularly impressed by the performance of the B. and S. engine, and, though from our preliminary examination, we were inclined to expect symptoms of overheating from the recessed cylinder head, we were entirely unable to extract a "knock" from the engine under the most trying circumstances. We are informed that the normal petrol consumption exceeds 100 m.p.g., and we were able to prove to our own satisfaction that the oil consumption is certainly not in excess of the normal.

In conclusion, the opinion of the new Barr and Stroud engine is that it is an extremely high-class production which is likely to carve out for itself a big future on account of its undoubted merits of silence, power, accessibility, and smooth running; it is adaptable to most standard lightweight frames.

If you have a query or information about Barr and Stroud engines please contact us