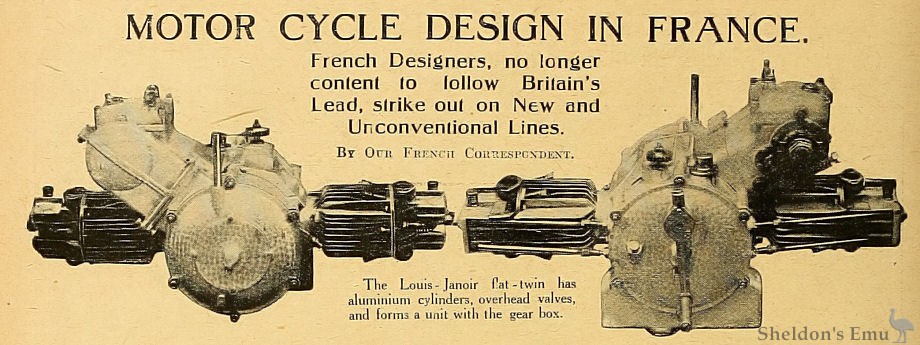

The Louis-Janoir Flat-twin has aluminium cylinders, overhead valves, and forms a unit with the gear box.

One of the T head cylinders of the Bleriot twin engine.

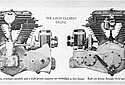

COMBINED ENGINE AND GEAR.

To combine the engine and gear box in one unit is regarded by French designers as an essential in modern design. It will be observed that all the machines described in this article follow this practice. Above is depicted the Bleriot unit, showing the side-by-side cylinders, kick-starter, and gear lever.

Combined "half-time" and change-speed gear of the Bleriot side-by-side twin.

The Bleriot vertical twin - a very compact design, in which mudguarding appears to have received serious consideration.

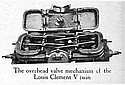

The overhead valve mechanism of the Louis Clement V twin

In the Louis Clement machine the clutch is mounted on the engine-shaft. The kick-starter is on the lay shaft of the integral gear box.

THE LOUIS CLEMENT ENGINE

An overhead camshaft and a shaft-driven magneto are embodied in this design. Both are driven through bevel gear.

The simple but hefty Louis Clement front fork and disc wheel is illustrated on the right.

Pressed steel construction is a feature of the Louis Janoir flat twin, which has a spring frame. Observe the padded seat.

Pressed steel construction is a feature of the Louis Janoir flat twin, which has a spring frame. Observe the padded seat.

French Designers, no longer content to follow Britain's Lead, strike out on New and Unconventional Lines.

By Our French Correspondent.

AFTER being stagnant for a number of years, French motor cycle design showed a wonderful revival at the last Paris Salon. On that occasion several machines were brought forth by new concerns and hitherto unknown engineers, in which were incorporated original ideas of such merit as to place them in a class by themselves. France had so long been content to follow timidly in the wake of England, in so far as motor cycle design and production was concerned, that the appearance of the new school created no little surprise among those who attended the show.

Machines on exhibition last October were nothing more than sample models. Nearly all of them were incomplete, and in the interval many details have been modified as the result of extensive tests on the road. At the present time, eight months after they were first shown to the public, some of them are ready to go into production, while others will still be several months before they are offered for sale.

As the most typical of the new French design, the Louis Clement twin may be selected. The engine was designed and built by M. Calvignac before the war, and in a frame of quite ordinary design was in service throughout the hostilities. Improved and modified, it was placed on exhibition at the Salon, and after further modifications, made possible by modern production methods, it is ready to be offered to the public.

The outstanding feature of this machine is that the two cylinders, of 52 x 90 mm. bore and stroke, mounted at an angle of 55° on an aluminium crank case, have a common detachable head carrying the valves, the camshaft, the cam operating mechanism, and combining the intake and the exhaust manifolds. There is a detachable cover over the head, so that no moving parts are visible, and the whole of this mechanism runs in a bath of oil. In addition to this feature, the engine and the gear box form a compact unit, which naturally tends toAvai'd lightness, as well as longevity, for all working parts are completely enclosed. As can be gathered from the illustrations, the drive IS taken from the crankshaft to the gear box by a short, enclosed chain, and the final drive is taken to the rear wheel by a second chain inside a detachable housing. A spring hub assures a perfectly flexible drive.

Enclosed Drive.

Reverting to the engine, the crank case forms a two-piece aluminium casting, divided horizontally, and forming two compartments, the front one enclosing the crankshaft, with its internal flywheels. the mutiple-disc clutch and the sprocket for the main driving chain. The rear compartment is a three-speed gear box, with sliding gears, and with sprocket for the final drive by chain. All the shafts are mounted in ball bearings. The pistons are of aluminium, and the I section connecting rods have roller bearing big ends. A bevel pinion on the extremity of the crankshaft drives an enclosed vertical shaft which operates the transverse camshaft in the detachable head.

There are four cams operating the vertical valves by means of very long rockers. One of the patented features of this engine is the simple method of adjusting the valve stem clearances. The valve stem has a flat screwdriver type end, while the extremity of the cylindrical portion is threaded. A special nut with a flat head from which project twin studs, screws on to the end of the valve stem, and also receives the forked end of the rocker. The fork, while operating the valve, also prevents the nut from turning To get adjustment, it is only necessary to lift the rocker clear of the valve and turn the nut in the required direction.

The detachable head, which is secured to the two cylinders by means of eight studs, has the intake and the exhaust passages cast with it. The carburetter, a horizontal Zenith, is thus bolted up direct to the head, without the use of any external intake piping. The main air supply is from two opposed points on the exhaust side of the cylinder head, passing right through it to the intake valves on the opposite side. This not only gives a uniform heating of the mixture, which tends toward economy and even running, but the cold air cools the oil bath forming a part of the head. As there are no plain bearings in the engine, drip feed is used from a tank to the detachable head, and by means of an overHow in this to the bare chamber through the vertical shaft housing. The magneto, as can be seen, is placed on the top of the gear box, and driven by means of a horizontal shaft with bevel gearing. The engine, which has a piston displacement of 540 c.c., runs at 2,500 revolutions, at which speed it is declared to develop 8 h.p.

Steel tubes are only used to a limited extent by the Louis Clement engineers, and brazing has been done away with almost entirely. The front fork, for instance, is a steel stamping, carrying at its upper rear extremity a forced steering pivot. Front suspension is by means of a four-leaf spring shackled at its front end. Both spring and shackle work under ideal conditions, for they are enclosed in a metal housing which constitutes the front number plate. Pressed steel is also used for what is generally described as the top tube In this case it should be described as the top frame member. It is in two parts, riveted together, and encircles and is welded to the head. Demountable and interchangeable disc wheels are another very good feature.

These are built up of a cast aluminium hub, forming brake drum, aluminium discs, and a steel rim. The rear wheel can be taken out, leaving the chain, sprocket, and brake bands in position, and either the front or the sidecar wheel can be put in its place. The advantage of this when it is necessary to repair a puncture on the roadside-in bad weather will be fully appreciated by all practical motor cyclists. The front wheel brake is operated from the handle-bar by means of a Bowden wire. The rear wheel brake control is by means of a pedal operated by the left foot. When a sidecar is used, this is also braked by the left foot.

As there is no tube above the tank, the speed indicator and clock are recessed in this latter with very neat effect. A pressed steel tool box is fitted, the top of which forms a strong luggage carrier. A machine of an entirely different type, but no less original, is the flat twin 8 h.p. Janoir. This has been considerably modified since it was first shown at the Paris Salon, the greatest change being the abolition of all steel tubes. The engine has cylinders measuring 85x85 mm. bore and stroke giving a piston displacement of 965 c.c. The crank case and the two cylinders are a single aluminium casting with pressed-in steel liners and a detachable cylinder head with cast iron valve seats. With this design there is no joint, and consequently no holding-down bolts at the cylinder base. The crank case is cylindrical, and is closed by two circular steel end plates, which on being removed give complete access to the internal organs.

When the right-hand plate is taken off, for instance, it shows the skew gear-driven vertical camshaft, with its four cams, the drive at the lower end for the oil pump, and at the upper end for the high-tension magneto. The main supply of oil is contained in the aluminium sump, but there is also an auxiliary supply within a tank in the frame of the machine. The balanced crankshaft with its two throws at 180° is carried in ball bearings, and has connected to it tubular rods with split big ends. The gudgeon pins are hollow, and work in aluminium pistons with bronze bushings. It is declared that this engine gives off 11 h.p. at 2,000 revolutions, and 16 h.p. at 3,200 revolutions. No attempt will be made to get the highest power out of the engine, but rather to adopt a moderate compression and get a very flexible and smooth running machine. Before leaving the engine, it should be stated that starting is by means of a crank, as in the case of a car engine.

Mounted on the top of the crank case, as clearly shown in the illustrations, is a compact three-speed gear box with sliding gears. Connection is made from the engine shaft to the gear box by means of a chain, contained in a dustproof and oiltight aluminium housing, and the final drive is taken by chain. A gate type change speed mechanism, with its lever conveniently placed to the driver's right hand, is made use of. One of the features of this is a simple locking arrangement by means of a flat blade spring which automatically locks the lever in position on the sector as each gear is successively engaged.

Mention has already been made of the fact that no steel tubes are employed, if exception be made of the handle-bar and the two small tubes for the luggage carrier. The front fork consists of two pressed steel members, the top bar of which is curved. They are united by three pins, the centre one receiving the head piece, and the two end ones being the shackle bolts of opposed leaf springs. This general arrangement is clearly shown in one of the illustrations.

A triangular pressed steel open frame is used, and the engine is bolted into it by a series of bolts going through the end plates of the crank case. At the rear a pressed steel fork, only slightly inclined from the horizontal, is used, with suspension by means of quarter-elliptic springs.

As can be judged from the illustrations, a very low centre of gravity is obtained. The petrol tank is carried within the open pressed steel frame, and at first sight appears to extend from the head to the spring cushion seat. This is not so, however, for the tank stops some distance from the seat, and the intervening space is filled up with a detachable metal cover, by removing which access is obtained to the carburetter and the magneto immediately below and on the top of the engine housing. While being thoroughly protected, these two organs are most conveniently placed for attention and adjustment.

Wire wheels are employed on the but they are interchangeable, detachable, and self-centring. No tools are required to change a wheel, and in the case of the rear, the chain, the sprocket, and the two brakes remain in position when the wheel is taken out. Wheel size is 750x85 mm. In the Bleriot twin an entirely different design has been adopted. Engine and gear box form a unit attached in a more or less standard type of frame. The two vertical cylinders are mounted side by side on an aluminium base chamber, with the exhaust valves facing forward, and the intake valves, the carburetter and the magneto at the rear. The crankshaft has a single throw, the two pistons thus moving up and down together. It is admitted that the balance does not approach that of the flat twin, although this defect has been overcome to a certain extent by light reciprocating parts. On the other hand the cooling is excellent and uniform. Piston displacement is 500 c.c., the cylinder bore being 50 mm., and the piston stroke 88 mm. Excellent features of this engine are the neat arrangement of the exhaust pipes, with perfect cooling; the short intake pipe with the very accessible carburetter; the well protected magneto; the spark plugs conveniently placed in the centre of the combustion chamber; and the enclosed valve stems.

The multiple disc clutch and the two-speed gear set are contained in the rear portion of the crank case housing. From the main shaft the drive is transmitted through the timing gears to a lay shaft on the extremity of which is mounted the driving pulley. This shaft runs at half engine speed. The lower gear is obtained by means of a dog clutch and operation is simple and easy.

The Bleriot machine is supplied with detachable disc wheels. The mudguards are particularly big, and tend to give a massive appearance to the machine. It has been found, after long road tests, that this width of guard is not really required as a protection against mud, and in consequence the size has been reduced since the machine was first exhibited.

It is stated that the same type of engine, but of 1,000 c.c., will be used in the Bleriot Whippet cycle car to be built in France. The Bleriot company being one of the biggest aeroplane concerns in France, it is quite natural to find that the sidecars are built up in the same manner as aeroplane fuselages. The lines are particularly pleasing, while the design and the high-class workmanship give lightness with great rigidity.

Engine Units.

These three machines, the Clement, Janoir, and Bleriot, are typical of the new French school. They do not, however, exhaust the activities of French motor cycle manufacturers. The product of the Gnome and Rhone Company need hardly be mentioned, for this is built entirely to the British A.B.C. designs.

An entirely French design is the Ballot two-stroke, built by the largest engine producing firm in France, with a reputation not confined to that country. It is not the intention of Ballot to produce a complete motor cycle, but to supply the engine only. This is now in production and will he used exclusively by the Alcyon Company. Other firms have arranged to lake it up, and the entire output for the next four years is said to be booked. The engine is a unit with its gear set and all control levers. Among its features are the complete enclosing of all working parts. Even the magneto is placed in a dust-proof aluminium casing. Among the French engine specialists, mention should also be made of Anzani, who produced motor cycle engines long before he became interested in aeroplane engines, and who is again devoting his chief attention to power plants for two-wheelers and for cycle cars.

The Motor Cycle July 29th, 1920. PP 122, 123, 124, 125

See also Paris Salon 1921

If you have a query or information about French motocyclettes please contact us