Quite a few eyebrows were raised when Phelon and Moore Limited, the Yorkshire-based manufacturer of Panther motorcycles, decided to make a dirtrack racer in 1928.

It was not so much that their move into this market was unexpected, as most of the other motorcycle manufacturers had already announced similar intentions. Panther, however, had little first-hand experience of racing and until 1924 had shown little interest in the Isle of Man TT.

An unexpected fourth place in the 1925 Senior race by an 18-year-old apprentice drafted into the factory team to replace an injured rider offered some encouragement. They had also built a very special machine for track and sprint racing, which was sent to South Africa during the winter of 1927 for Joe Sarkis to ride.

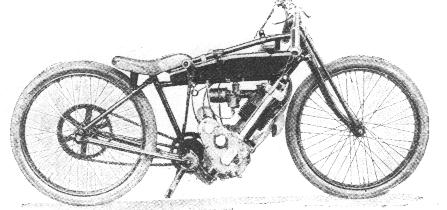

With enthusiasm for events of a more sporting nature beginning to run high at Cleckheaton, where it was made, it was fortuitous that the new sport of dirt-track racing should come along at just the right time. If nothing else, they had an engine design that showed considerable promise. When details of the machine were revealed, those close to this type of racing were quite taken aback. Not only did the new Panther look antiquated, it was seen to have been assembled from what appeared to be an odd assortment of parts.

The frame was that of the model used by Royal Flying Corps dispatch riders during the Great War, its unsprung front fork taken from a much earlier 1904 model. The engine was mounted in the well recognised Panther position, inclined forward at an angle of about 50 degrees. It formed a structural member as it replaced the front down tube of the more conventional type of frame.

The handlebars were of the dropped type, surmounted by an adjustable steering damper. The customary kneehook was provided, long and slender, and a single footrest sloping backwards was slung below it. The wheels were of 23in and 22in diameter respectively, front and rear. Without brakes and shod with beaded edge tyres, two security bolts were fitted to the rear wheel as a precaution against the tyre peeling off its rim.

The 498cc ohv engine had a bore and stroke of 84 x 90mm. It was also without the usual crankcase oil sump. Since the races were only of short duration it did not have a mechanically-driven oil pump. Instead a manually-operated oil pump on the tank top had been substituted, which drew oil from a separate compartment within the wedge-type fuel tank. A magneto provided the ignition and an Amac carburettor the mixture, the latter in a markedly updraught position. The exhaust system was simple in the extreme - a short stub from the single exhaust port projecting to the right.

The countershaft was unorthodox too. It was small enough to fit into the bottom, bracket of the frame occupying the position usually taken up by the pedalling gear of a bicycle. It was, in effect, one half of the old P&M; two-speed gear, similar in many respects to the centrifugal clutch found on mopeds. It differed in being manually operated by inserting a wedge between the two driven shoes to separate them and bring them into contact with the drum that surrounded them. In some respects, this could have proved an advantage because it meant the engine could be freed from the final drive. Not that it mattered very much as races began on a rolling start basis and it was not until the starting gate was invented that clutches became a necessity.

The manufacturers reduced the overall weight to a remarkable 185lb which, for a 500cc single at this time, must amount to a record. Each machine was hand-built and sold to order direct from the works at Ł85. Not surprisingly very few were sold, and there is no record that they had any successes on the dirt or for that matter in any speed events.